GET TOUCH

+91 - 8446312333

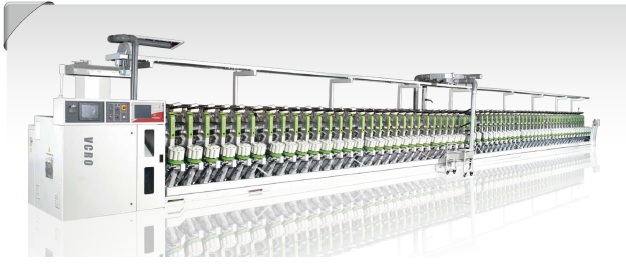

Winding Machinery

Textile Winding Machinery: Precision, Efficiency, and Innovation

At [DE Globalconsulting], we offer advanced Winding Machinery designed to optimize your yarn and fabric production processes. Our high-performance winding machines are engineered for a wide range of applications, including the winding of yarn, filament, and fibers in various textile industries. Whether you’re working with natural fibers, synthetic yarns, or specialized threads, our machines deliver exceptional quality, speed, and efficiency to meet the needs of modern textile manufacturing.

We combine innovative engineering with the latest technology to ensure that our winding solutions improve productivity, reduce operational costs, and increase the overall quality of your final product.

Our Range of Winding Machines

We provide a comprehensive selection of winding machinery tailored for different stages of textile production. Our machines are built to deliver consistent results and are equipped with advanced features to enhance operational efficiency.

- Bobbin Winding Machines Our Bobbin Winding Machines are designed to provide high-speed and precision winding for yarns and threads. These machines ensure even tension, uniform winding, and excellent package quality, making them suitable for various yarn types and applications. With fully automated systems, they are ideal for continuous operations in high-volume yarn production.

- Cone Winding MachinesCone Winding Machines are essential for winding yarn into cone-shaped packages. These machines offer superior winding performance, ensuring minimal yarn tension and perfect package formation. Ideal for both cotton and synthetic yarns, they help improve the efficiency of dyeing, weaving, and knitting processes. Our cone winders also feature advanced monitoring systems for real-time performance analysis.

- Ring Spinning Winding Machines Our Ring Spinning Winding Machines are designed to efficiently handle the winding of yarns produced from ring spinning processes. These machines provide the flexibility to wind different types of yarn with precision and minimal wastage. The automatic doffing and threading systems make it easier to switch between yarn batches, ensuring uninterrupted production.

- Friction Spinning Winding Machines Our Friction Spinning Winding Machines utilize advanced technology for high-quality winding of both staple and filament yarns. These machines feature friction-driven winding mechanisms that ensure smooth and consistent winding, even at high speeds. They are ideal for producing fine yarns used in high-performance fabrics, including technical textiles.

- Warp Winding Machines Designed for the preparation of yarn for weaving, our Warp Winding Machines are engineered to efficiently wind multiple ends of yarn onto beams or packages. These machines deliver superior yarn tension control, uniformity, and package consistency, making them suitable for all types of warping processes. The integrated control systems offer precise adjustments to meet specific warp requirements.

- TFO (Two-for-One) Twisting and Winding MachinesTFO Twisting and Winding Machines combine both twisting and winding functions in one process, reducing labor and energy consumption. These machines twist two yarns together before winding them onto a single package. They are perfect for creating textured yarns, which are commonly used in fabrics with stretch, durability, or unique visual effects.

- Cross Winding MachinesCross Winding Machines are used for winding yarns onto larger packages. These machines ensure a smooth and even cross-wound package that is ideal for further processing. They are commonly used in the production of filament yarns, where high precision is essential. Our cross winding systems are designed to reduce downtime and increase the efficiency of the winding process.

- Automatic Cone Winding Machines Equipped with advanced automation features, our Automatic Cone Winding Machines offer a high level of control over the winding process. These machines feature automatic bobbin changing, tension control, and cutting systems, ensuring precise package formation with minimal human intervention. Ideal for large-scale production, they help reduce labor costs and improve productivity.

- Textile Spool Winding Machines Our Spool Winding Machines are perfect for winding fine and delicate yarns onto spools. These machines ensure that yarn is wound evenly with controlled tension, avoiding any damage to the threads. With their precision and flexibility, these machines are commonly used in both the textile and sewing industries.

- High-Speed Winding Machines Our High-Speed Winding Machines are designed for maximum efficiency and minimal downtime. These machines are ideal for high-speed production environments and are built to handle large volumes of yarn without compromising on quality. Their automated features reduce manual handling, ensuring consistent and accurate winding results.

Why Choose [DE Globalconsulting] for Winding Machinery?

- Precision and Quality: Our winding machines are engineered to ensure perfect package formation, consistent tension, and minimal yarn breakage. We use the latest technology to ensure that every package of yarn is wound to the highest standards of quality.

- Automation and Efficiency: Our machines feature advanced automation systems that reduce manual intervention, increase production speed, and enhance the consistency of the winding process. With fully automated setups, your operations run smoothly with minimal downtime.

- Energy-Efficient Designs: We understand the importance of reducing operating costs. Our winding machines are designed with energy-efficient features that lower power consumption, making them both cost-effective and environmentally friendly.

- Flexibility for Various Applications: Whether you’re producing yarn for apparel, home textiles, or industrial fabrics, our machines are versatile enough to handle a wide range of yarn types, including natural, synthetic, and blended fibers.

- Advanced Control Systems: Our winding machines come with integrated smart control systems that offer real-time monitoring, performance tracking, and diagnostics. This allows for remote management, ensuring optimal performance and immediate troubleshooting.

- Robust Support and Maintenance: We provide end-to-end support, including machine installation, training, and maintenance services. Our experienced technicians are always available to ensure your winding machines are performing at their best, helping you avoid unnecessary downtime.

- Customizable Solutions: We understand that every manufacturing operation is unique. Our winding machines can be customized to meet specific production requirements, including speed, package size, and winding style. Our team works closely with you to provide solutions tailored to your needs.

Enhance Your Production with [DE Globalconsulting]'s Winding Machinery

At [DE Globalconsulting], we are committed to delivering the most innovative and reliable winding machinery that helps you maximize productivity, ensure quality, and reduce costs in your textile manufacturing operations. Our machines are designed to meet the needs of both small-scale operations and large textile production plants.

Contact us today to learn more about our Winding Machinery Solutions and how they can improve the efficiency and quality of your textile production. Let us help you take your manufacturing to the next level.